Applications

Engines & Casings

Cold cure composite materials for the long-term repair and protection of industrial engines and casings against impact, erosion and corrosion damage.

Fans, Blowers & Compressors

Fan, Blower and Compressor Repair and Protection. Durable abrasion and corrosion resistant composite materials and epoxy coatings for the repair and protection of fans, blowers and compressors.

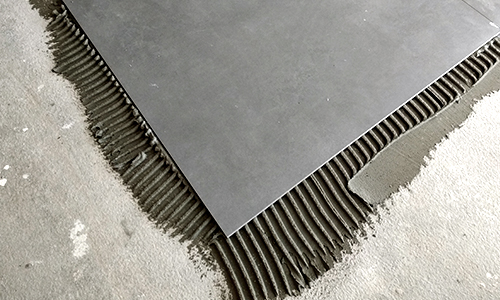

Floor Problem Areas

Belzona offers a variety of concrete repair composites, coatings and slip reduction systems for concrete and stone floor repair, resurfacing and protection.

Gaskets, Seals & Shims

Belzona provides a range of composite materials for the creation and repair of gaskets, seals and shims, including both high compressive strength materials and flexible solutions.

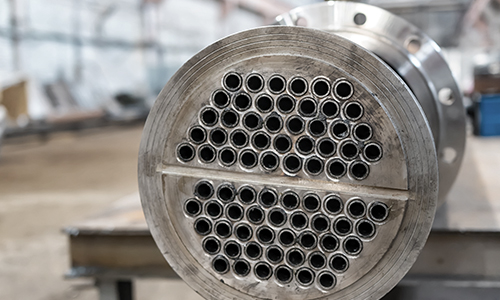

Heat Exchangers

Belzona offers a wide range of metal repair composites and epoxy coatings to repair damaged heat exchangers and provide erosion and corrosion protection.

Mechanical Power Transmission

Corrosion resistant composite materials for the repair and protection of worn mechanical power transmission equipment to ensure reliable performance.

Pumps

Belzona provide a wide range of metal repair composites and epoxy coatings to rebuild and protect pumps damaged by erosion-corrosion, as well as to increase their efficiency.

Roof Problem Areas

Seamless and cold-applied liquid roof coatings for the repair and protection of roofs against damage, deterioration and water ingress.

Ships & Offshore Structures

Belzona provides a wide range of metal and rubber repair and protective composites to restore and protect ships and offshore structures versus corrosion, erosion and mechanical damage.

Solids Handling Machinery

Abrasion resistant composite materials for the repair and protection of material handling equipment.

Tanks & Chemical Containment Area

Belzona provide a wide range of metal and concrete repair composites and epoxy coatings to repair storage tanks and secondary containment areas and protect them from the effects of erosion, corrosion and chemical attack.

Valves, Pipes & Fittings

Cold-curing composite materials and epoxy coatings to repair and protect valves, pipes and fittings damaged by erosion, corrosion or chemical attack.

Wall Problem Areas

Reforming and Protective Materials. Belzona repair composites and polymeric coatings repair walls and protect against water ingress, physical, chemical and bacterial attack.